Iron-based structures of industrial heritage – Sensor-based and data-driven AI system for structural health monitoring of large-scale objects of industrial and cultural heritage

Industrial structures that are considered as monuments at the end of their working lives were never intended to exist forever. After shutdown changed conditions occur that lead to conservation challenges. These include in particular the progressive corrosion of the iron-based structures. Material preservation requires condition monitoring for target-oriented maintenance. Up to now, the time-consuming monitoring has been carried out on an object-by-object and measure-by-measure approach. According to the current state of the art, a target-oriented condition evaluation and the downstream verification of action strategies for proactive maintenance measures are not required. With this background, the goal is to develop and implement a sensor-based and data-driven structural health monitoring (SHM) by using artificial intelligence (AI).

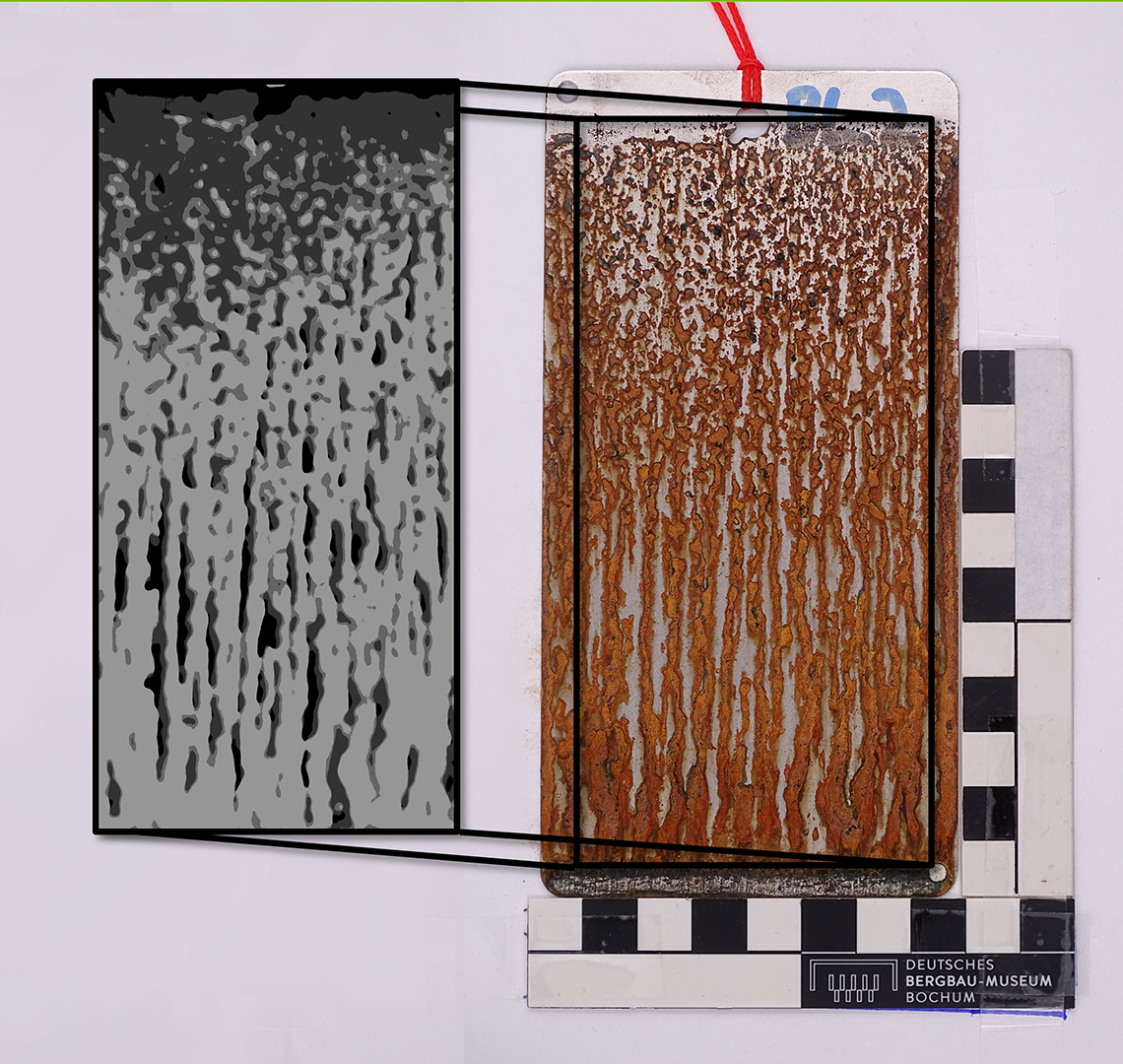

To achieve this goal, a structured and universal method for condition characterization will be developed, that enables a precise description of the initial condition and a sensor-based classification of the damages at objects of industrial heritage. Generating in-situ and ex-situ measurement data will provide an in-depth understanding of acting corrosion mechanisms at the object. Based on these results, corrosion will be reproduced in analog laboratory-experiments. Controlled laboratory conditions of the accelerated aging tests will also lead to defined reference conditions, that will be used for the pre-training of the AI with respect to corrosion detection and classification. The application of transparent corrosion protection coatings simulates the optical changes of the surface by object protection measures in laboratory scale and the AI training data set is extended. An aerial inspection of the object by drones allows an efficient and semi-automatic condition monitoring.

An objective reference is generated by means of sensor-based damage mapping. This enables the calibration of drone applied optical measurement systems (multispectral and infrared) and the generation of training data. By repeatedly inspecting of areas with high damage concentration, the damage mapping is updated in selected sub-areas and analyzed by the AI system. The comparison of the automatic damage segmentation with the measurement-based data from the updated damage mapping allows a detailed determination of the detection accuracy and validation of the system. Deep learning is used to form a drone-based SHM system with a high degree of automation. By continuous object aerial inspection, a close-meshed condition evaluation is enabled that automatically detects critical damage concentrations.