In view of the fact that around 200 of the 226 existing vaulted bridges were demolished between 2015 and 2019, a rethink in terms of continued use is required due to the increased residual load-bearing capacity:

Against the background of the increased demolition of vaulted bridges, the question must be asked: “Why is preservation so difficult?”

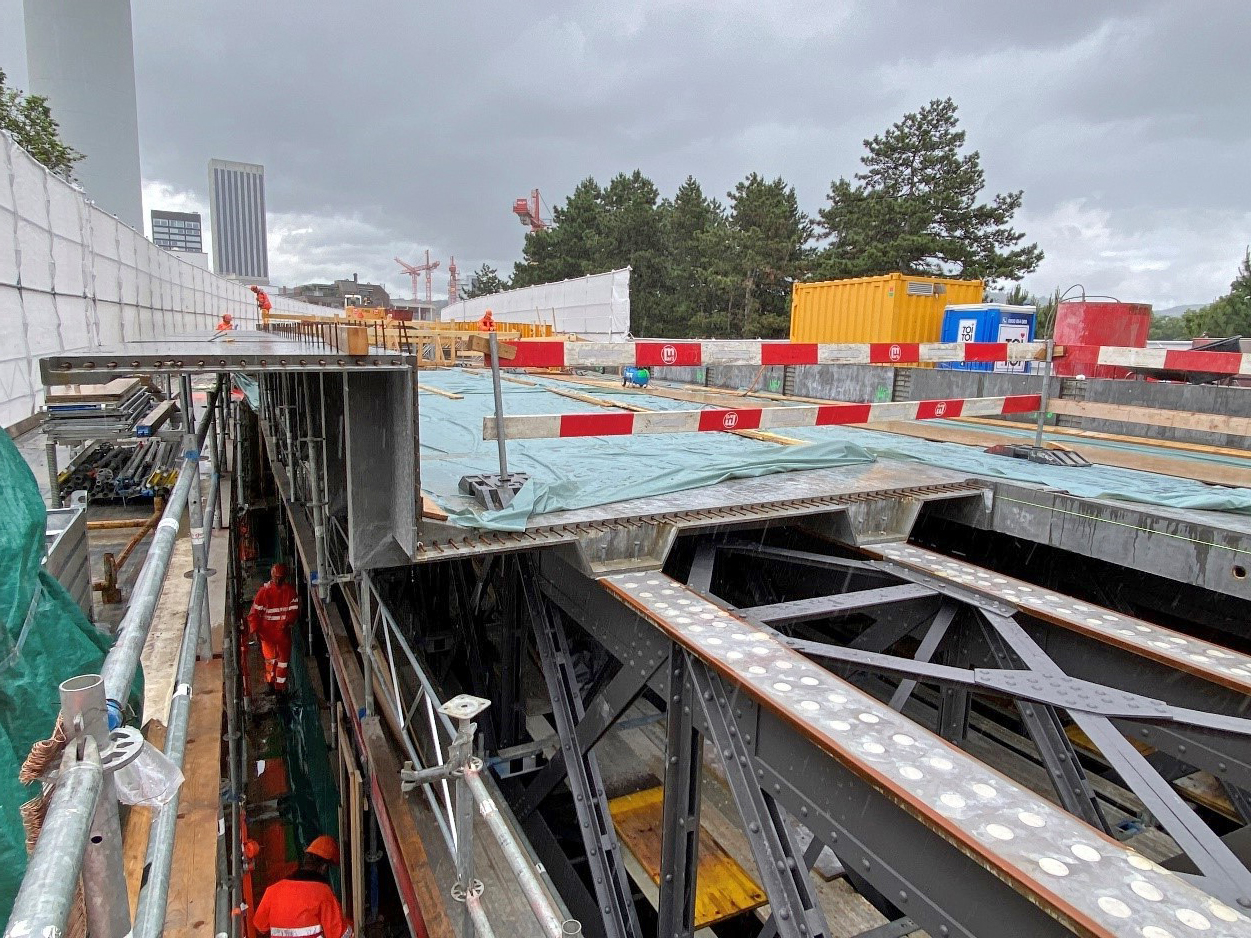

Prof. Marx entered the race for the endowed professorship of DB InfraGO AG (then DB Netz AG) in 2020 with this question in mind. In addition to the topics of reducing rail extensions and slab track, the above-mentioned topic was decisive. Due to the false motivation of the performance and financing agreement set up by the federal government at the time, in which full funding was provided for the new construction, this was the free ticket to remove the old structure. (Figure 1)

In the first step, the financing structure was adapted by defining a list of criteria that set out mandatory measures for the continued use of a vaulted bridge. After consultation with the Federal Railway Authority, a general refurbishment with structural improvement, injections, stone replacement and further measures in the substructures is now also eligible for federal funding.

As historic vaulted bridges have an enormously high residual load-bearing capacity and over 90% of their basic substance is still in use, the next step was to place a framework contract tool for structural diagnostics with Deutsche Bahn. Here, the investigation planning and subsequent diagnostic sampling of the building fabric can take place in a two-stage program. This means that the potential further use can be determined quite quickly at an early stage. Furthermore, the maintenance regime for vaulted bridges was adapted so that after 149 years of service life, a general refurbishment with corresponding structural improvement and measures on the back of the vault, such as a roadway slab formation or structural back sealing, is carried out. Based on expert project support for vault measures at Deutsche Bahn via the TU Dresden, more than 50 measures were transferred to maintenance that were previously set for demolition and new construction. Based on the knowledge gathered there and the obstacles that led to premature demolition in the projects, a technical set of rules was developed in the form of a modular supplement in RIL 804.

With these boundary conditions, it is now possible to create and optimize a synergy with the static verification procedures for vaulted bridges in RIL 805. For this purpose, the program for load runs on arched bridges on the railroad was adapted in cooperation with the TU Dresden. Using defined locomotive loads, the deformation of a vault is to be determined as a function of the soil-structure interaction, see Figure 2. This allows static calculation models to be calibrated subsequently and simplified methods can be used in the future to successfully verify the load-bearing capacity of vault bridges.

Another point is the use of innovative, modern building materials such as ultra-high-strength fiber-reinforced concrete (UHFB) or textile-concrete back waterproofing (with non-metallic reinforcement) on existing structures such as arched bridges. The new materials can be used on vaulted bridges both as structurally and statically effective sealing layers. The UHPC in particular could be transferred to the German pilot phase thanks to the knowledge of Prof. Brühwiler at the EPFL and the application cases of the Swiss Federal Railways (SBB) via the engineering office Marx Krontal Partner. The product has been researched in Switzerland for several decades and has a significantly higher compressive strength and durability compared to conventional reinforced concrete thanks to the introduction of steel fibers. As a result of these requirements, significantly slimmer cross-sections and a lower use of materials can be pursued, as shown in the application cases, see Figure 3 and Figure 4 of the SBB. The aim of using innovative construction materials such as UHPFRC is to achieve the same speed of refurbishment of an existing bridge as the insertion of a new frame structure by means of slender cross-sections and the associated high early strength.

With these processes, the structured continued use of railroad vault bridges, a guide/template is created to transfer the rethinking to other forms of construction, such as steel bridges.

Abbildung 1: „Warum ist Erhalt so schwer?“ – Abbruch einer Gewölbebrücke mit einem Bogen und Ersatz durch ein in Seitenlage errichtetes Stahlbeton-Rahmentragwerk. Quelle: Wadle Bau

Abbildung 2: Belastungsversuch an einer Gewölbebrücke der Deutschen Bahn – mechanische und lasergestütze Messeinrichtung zur Ermittlung der Verformungen während Überfahrt von Zügen, Quelle: Pelka